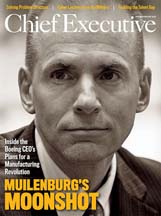

If anyone thinks U.S. manufacturing is in decline, have them talk to Dennis Muilenburg. After serving as Boeing’s COO, the Iowa native and aerospace engineer took over the top job from Jim McNerney in 2015, and he has been on a tear ever since, driving the nation’s leading aerospace and defense company—and America’s biggest exporter—to find another gear to compete in an increasingly complex, global and interconnected world.

The reason is simple: Opportunity. The growth in commercial airplanes has been paced by worldwide passenger growth of 5 percent to 6 percent a year. But in places like China and India traffic growth runs as much as 15 percent a year. Every year in Asia, 100 million people fly for the first time on an airplane, and estimates are that barely 20 percent of the world’s population has ever flown in a commercial airplane. This is a big, high-scale growing manufacturing sector that companies like Boeing need to fuel for the future. It’s about a $7.5 trillion marketplace over the next 10 years.

“To compete in this environment,” says Muilenburg, “we cannot continue to just improve incrementally. Incremental productivity improvements of 1 percent to 4 percent a year will not allow us to compete in the future. We are focused on step-function improvements that are measured in 20 percent, 50 percent, 70 percent to 90 percent increments in some of our key value chains inside of our factories.”

Getting there won’t be easy. Boeing’s scale is almost unimaginable. From its headquarters in Chicago, the $94.6 billion juggernaut employs more than 140,000 people across the U.S. and in more than 65 countries. In the U.S. alone, Boeing employs 50,000 factory workers and 45,000 engineers.

Muilenburg’s ambitions obviously have big implications for the rest of American manufacturing as well. While the prevailing narrative is that nothing can be done to stop the continuing decline of U.S. industry at the hands of cheap global labor and disruptive technology, Muilenburg is staking his company’s future on technology unlocking productivity gains and on finding growth in new parts of the value chain.

It’s a playbook worth reviewing as manufacturers across the U.S. seek to find and hone advantages to win in an ever-more competitive world. According to recent analysis of current industry trends and performance, the McKinsey Global Institute finds that the U.S. could boost annual manufacturing value-added by up to $530 billion (20 percent) over current trends by 2025.

Four Keys to Transformation

The key, of course, is productivity, and Muilenburg has been pushing this hard using a variety of tools: 3D printing, digital throughputs, selective automation. For example, production speed has been rising steadily in its Renton, Washington, facility, where the company builds its 737s—among the most widely used passenger aircrafts in the world today. In 2016, it was building 737s at a rate of 42 a month in the same space that was originally created to build 17 a month.

At the end of 2016, it ramped up that line to 47 a month and is on track to begin producing 52 a month this year, then 57 a month in 2019. Soon the facility will be building roughly two 737s each day—the highest production rate the company has ever had in commercial airplanes.

Chief Executive Group exists to improve the performance of U.S. CEOs, senior executives and public-company directors, helping you grow your companies, build your communities and strengthen society. Learn more at chiefexecutivegroup.com.

0

1:00 - 5:00 pm

Over 70% of Executives Surveyed Agree: Many Strategic Planning Efforts Lack Systematic Approach Tips for Enhancing Your Strategic Planning Process

Executives expressed frustration with their current strategic planning process. Issues include:

Steve Rutan and Denise Harrison have put together an afternoon workshop that will provide the tools you need to address these concerns. They have worked with hundreds of executives to develop a systematic approach that will enable your team to make better decisions during strategic planning. Steve and Denise will walk you through exercises for prioritizing your lists and steps that will reset and reinvigorate your process. This will be a hands-on workshop that will enable you to think about your business as you use the tools that are being presented. If you are ready for a Strategic Planning tune-up, select this workshop in your registration form. The additional fee of $695 will be added to your total.

2:00 - 5:00 pm

Female leaders face the same issues all leaders do, but they often face additional challenges too. In this peer session, we will facilitate a discussion of best practices and how to overcome common barriers to help women leaders be more effective within and outside their organizations.

Limited space available.

10:30 - 5:00 pm

General’s Retreat at Hermitage Golf Course

Sponsored by UBS

General’s Retreat, built in 1986 with architect Gary Roger Baird, has been voted the “Best Golf Course in Nashville” and is a “must play” when visiting the Nashville, Tennessee area. With the beautiful setting along the Cumberland River, golfers of all capabilities will thoroughly enjoy the golf, scenery and hospitality.

The golf outing fee includes transportation to and from the hotel, greens/cart fees, use of practice facilities, and boxed lunch. The bus will leave the hotel at 10:30 am for a noon shotgun start and return to the hotel after the cocktail reception following the completion of the round.