Make Or Buy? It Was Biggest Decision For Marshmallow Manufacturer

Many mid-market manufacturers face a big decision as they attempt to scale up: To make or buy their goods?

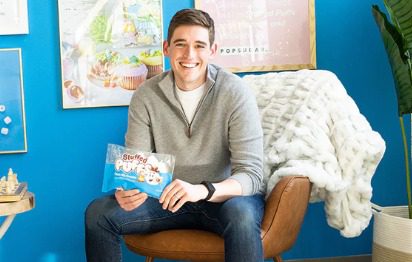

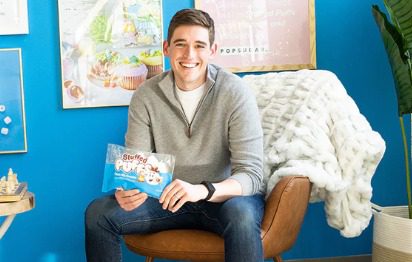

Michael Tierney spent eight years trying to find a contract manufacturer capable of making his chocolate-stuffed marshmallows before he finally gave up, built his own facility and began manufacturing them on his own. And in the space of just three years, being in control of his own production has been a key to the rapid growth of Stuffed Puffs into a $60-million brand that is sold in Walmart stores nationwide and backed by about $150 million in capital.

“We had a binary situation,” Tierney, a former highly rated Michelin chef who founded Stuffed Puffs in 2012 based on his highly indulgent marshmallow recipe, told Chief Executive. “And now we’ve spent more than $100 million just in manufacturing assets.”

Tierney was convinced more than a decade ago that his product idea was great but couldn’t find an existing manufacturer — and there are hundreds of contract makers in the food industry — that could wrap its machines around key attributes of Stuffed Puffs. “We needed closed ends on the sides of the marshmallow and a certain volume of chocolate on the inside to make it work,” he said.

Existing commodity marshmallow makers such as Kraft Heinz weren’t capable of making such a product, Tierney said, and neither were any of the other contract manufacturers that he visited in Mexico, Central America and elsewhere. So Tierney retrofitted a small facility in Wisconsin with his own machines to make his own production runs for Stuffed Puffs beginning in late 2018.

Then, after Walmart picked up the product line in 2019, Tierney quickly ran out of capacity. And after getting backing in the amount of tens of millions of dollars from Factory, a venture-capital firm spawned by Freshpet founder Richard Thompson in Bethlehem, Pennsylvania, Tierney pivoted quickly to building the company’s own 165,000-square-foot facility in Pennsylvania’s Lehigh Valley. It now employs about 150 people turning out thousands of gourmet marshmallow treats.

Here is some of Tierney’s advice for manufacturers’ make-or-buy decisions:

• Gauge the importance: Not every manufacturer must control its own output to get the products it wants, but the uniqueness of Stuffed Puffs compelled Tierney to set a high bar for manufacturing quality that, as it turned out, only his oversight could mount.

“We were realistic that if we embarked on our own manufacturing it would require lots of outside capital,” he said. “And we were scaling so quickly that we had to be cognizant of our capital needs, which are a step function different than if you’re co-packing.”

• Value control: “When you co-pack, you aren’t the priority, and you’re probably not their largest customer, and you have no control over the plant,” Tierney said. “We have 150 people and they think about nothing but Stuffed Puffs. That helps us massively .when we have conversations with a Walmart: We can be in control, versus having to walk away from opportunities.”

• Forecast carefully: The stakes are higher with your own facility. “You need to be much tighter in your ability to forecast your business because you’ve been entrusted with the livelihoods of 150 or 160 people and their families,” Tierney said. “You’d better be able to continue to support that with your volume and scale. If you’re getting co-packing, you can fluctuate your volume and scale and your team.”

• Get help: Manufacturing is an area of special knowledge that outstrips the understanding of most entrepreneurs, and the wise ones quickly understand that. “You have to know what you don’t know and be willing to bring in appropriate help through engineering, construction and layout,” said the ex-chef. “There are people way smarter than you about that. I controlled the technology we own as intellectual property but made sure we surrounded ourselves with smart people.”

• Leverage automation: “We put automation in places that were critical for our process,” Tierney said. “Since we built the facility from the ground up, we had the luxury of not having to upgrade but of buying the latest and greatest technology to outfit from day one. And we could design for our business around the team members we were going to hire.”

Chief Executive Group exists to improve the performance of U.S. CEOs, senior executives and public-company directors, helping you grow your companies, build your communities and strengthen society. Learn more at chiefexecutivegroup.com.

0

1:00 - 5:00 pm

Over 70% of Executives Surveyed Agree: Many Strategic Planning Efforts Lack Systematic Approach Tips for Enhancing Your Strategic Planning Process

Executives expressed frustration with their current strategic planning process. Issues include:

Steve Rutan and Denise Harrison have put together an afternoon workshop that will provide the tools you need to address these concerns. They have worked with hundreds of executives to develop a systematic approach that will enable your team to make better decisions during strategic planning. Steve and Denise will walk you through exercises for prioritizing your lists and steps that will reset and reinvigorate your process. This will be a hands-on workshop that will enable you to think about your business as you use the tools that are being presented. If you are ready for a Strategic Planning tune-up, select this workshop in your registration form. The additional fee of $695 will be added to your total.

2:00 - 5:00 pm

Female leaders face the same issues all leaders do, but they often face additional challenges too. In this peer session, we will facilitate a discussion of best practices and how to overcome common barriers to help women leaders be more effective within and outside their organizations.

Limited space available.

10:30 - 5:00 pm

General’s Retreat at Hermitage Golf Course

Sponsored by UBS

General’s Retreat, built in 1986 with architect Gary Roger Baird, has been voted the “Best Golf Course in Nashville” and is a “must play” when visiting the Nashville, Tennessee area. With the beautiful setting along the Cumberland River, golfers of all capabilities will thoroughly enjoy the golf, scenery and hospitality.

The golf outing fee includes transportation to and from the hotel, greens/cart fees, use of practice facilities, and boxed lunch. The bus will leave the hotel at 10:30 am for a noon shotgun start and return to the hotel after the cocktail reception following the completion of the round.