Busy CEOs may be forgiven for trying to tune out the noise and hype that technology suppliers try to generate. Remember the Y2K craze? But every once in a while, a technology reaches what Andy Grove, the first hire and ultimately chief executive of Intel, called the “strategic inflection point.” The technology’s cost falls dramatically and its performance rises equally dramatically. Grove was referring, of course, to semiconductors. But today, the same phrase applies to an entirely different field—Three-dimensional (3D) Manufacturing, also called Additive Manufacturing because parts and products are built one layer at a time by printers.

Busy CEOs may be forgiven for trying to tune out the noise and hype that technology suppliers try to generate. Remember the Y2K craze? But every once in a while, a technology reaches what Andy Grove, the first hire and ultimately chief executive of Intel, called the “strategic inflection point.” The technology’s cost falls dramatically and its performance rises equally dramatically. Grove was referring, of course, to semiconductors. But today, the same phrase applies to an entirely different field—Three-dimensional (3D) Manufacturing, also called Additive Manufacturing because parts and products are built one layer at a time by printers.

The evidence can be glimpsed at Pratt & Whitney, which has been developing 3D manufacturing techniques for 25 years. In a room at its headquarters in East Hartford, Connecticut, four big machines almost soundlessly print out 600 plastic parts a year—to be used as prototypes or for tooling and support for other metal parts. But now, the company says it is ready for the first time to place dozens of 3D-manufactured titanium and nickel parts on its PurePower geared turbofan jet engines. Engines with additively manufactured parts have been flight-tested and will power Airbus and Bombardier aircraft entering passenger service in the second half of 2015. The parts include fuel-bypass manifolds, mounts, fittings, brackets, oil nozzles and airfoils.

The strides that Pratt, a unit of United Technologies, and GE’s engine unit are making are attracting wide attention because jet engines are among the most precise and powerful machines in the world, and they are subject to incredible heat and stress.

“It’s like when IBM started in the personal computer business in the 1980s—the engine-makers have embraced the new technology and given it legitimacy,” says Howard Kuhn, a 3D expert and Distinguished Collaborator Award winner at America Makes, also known as the National Additive Manufacturing Innovation Institute, based in Youngstown, Ohio.

Aerospace isn’t the only sector demonstrating the power of 3D manufacturing. However, in other industries, small- to medium-sized businesses often lead the way. In the medical field, Oxford Performance Materials, a $10 million-a-year company, uses 3D manufacturing to make pieces of the human cranium out of a high-performance plastic and customizes them to fit the heads of patients who suffer head injuries. Likewise, in the dental field, Align Technology, a $660 million-a-year company, uses 3D manufacturing to offer customers largely invisible plastic spacers customized to each individual’s set of teeth. In other dental settings, patients can watch an implantable tooth be printed before their eyes.

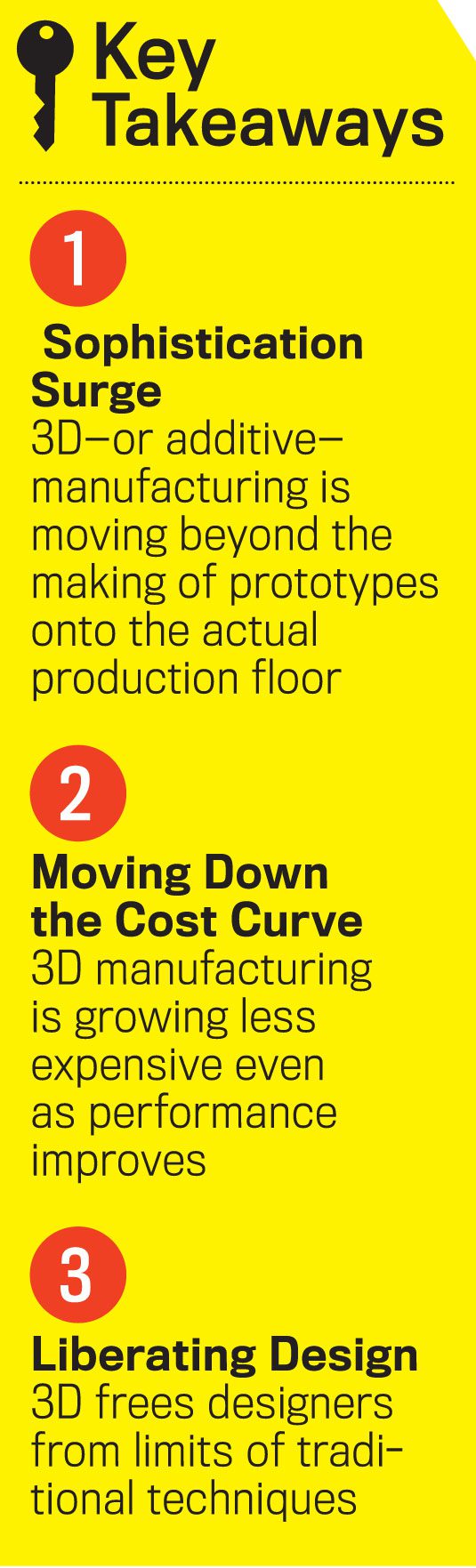

In short, 3D manufacturing is breaking out of the prototype stage, where it has lingered for many years, to full-fledged manufacturing.

Wohlers Associates, a top consultancy in the field, says 34.7 percent of the global market for additive manufacturing is now devoted to making parts for final products, as opposed to prototyping, molding and various types of tooling. That’s up from just 4 percent in 2003. Using 3D to make production parts passed the $1 billion mark globally in 2013 and about 38 percent of that activity was in the U.S. “We are seeing companies push the limits of additive manufacturing to new levels and apply the technology in entirely new ways,” says Terry Wohlers, president of Wohlers, based in Fort Collins, Colorado.

The reasons that 3D is suddenly catching on are many and varied. The costs of printing machines have dropped, and the machines are more automated and efficient. Also, scientists and engineers have made progress in understanding how various metals, plastics and composite materials can be made from powders and then bonded with lasers and other tools. Designers are recognizing that they can develop parts and not worry about whether the parts can be manufactured through traditional techniques, which is allowing them to craft parts that are dramatically different in appearance. Furthermore, companies are realizing they don’t need long manufacturing runs for specialized spare parts, as in military uses, because parts can be made on an as-needed basis. A 3D printer has even been sent to the International Space Station so that astronauts and scientists can print replacement parts rather than having them blasted up from earth.

This change has come about so fast that many CEOs of small- and medium-sized industrial companies now find themselves at a loss. “If you’re a CEO of a small or midsized company and you are not seriously investigating and investing in 3D printing and additive manufacturing, chances are you are placing your company in a significant, competitive disadvantage,” says Avi Reichental, chief executive of 3D Systems in Rock Hill, South Carolina. “You will be disrupted by other companies that compete with you because they will have these capabilities.”