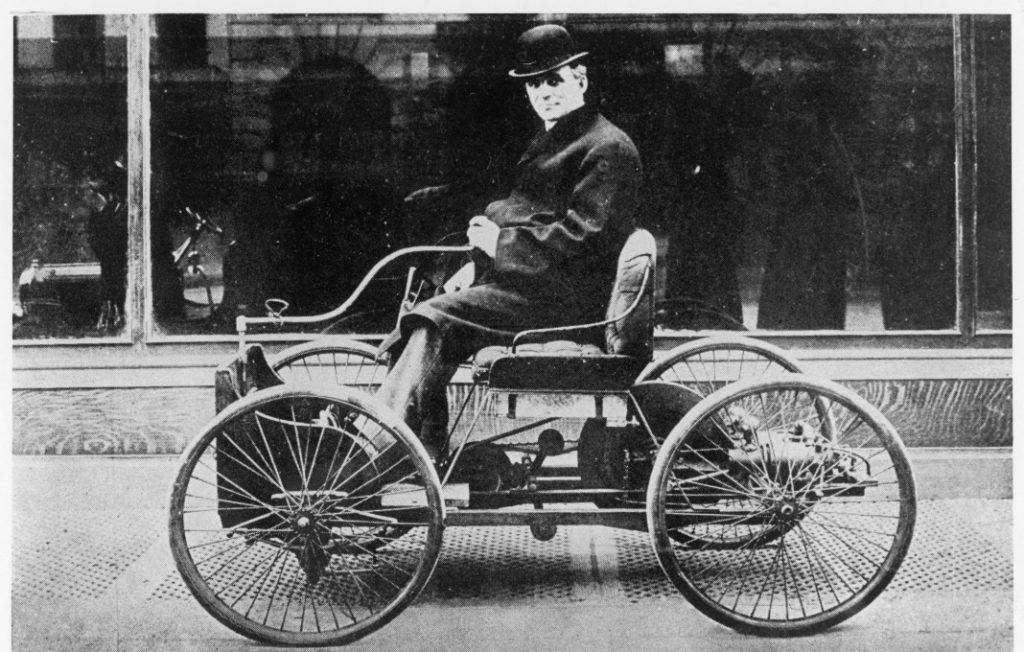

One of the most visionary and controversial entrepreneurs of all time is Henry Ford. And he’s been on my mind lately as I think about bettering my own business for the future.

One of the most visionary and controversial entrepreneurs of all time is Henry Ford. And he’s been on my mind lately as I think about bettering my own business for the future.

Predicting the future is always tough. How do you anticipate what will happen next, especially in uncertain times? We all hope that our sales improve and our costs go down, but what steps can we take as leaders to ensure that we’re safeguarding against unforeseen events? Here’s what we’re thinking about at Hint.

Automate What You Can

While many think of Ford as the inventor of the automobile, what he really innovated was the assembly line, which ended up changing every manufacturing industry. Automating products to go to workers via conveyor belt revolutionized the use of resources in factories. There were more than a few who felt that Ford was valuing systems over people. But he recognized a problem and had a solution that would streamline production for the future.

A few years ago, Hint started automating several portions of our business. We wanted to minimize the number of workers in the filling room at our plants because Hint is a natural, preservative-free product. We needed to avoid the spread of germs that could be caused by someone sneezing on the line during the bottling process. By late 2019, we had achieved our goal. While I can’t say we automated in preparation for a pandemic, it certainly kept our line running and avoiding a shutdown this past year.

Get as Local as Possible. Now.

Even Henry Ford believed in staying as local as possible. Bringing everything under one roof would increase the speed of production and bring down costs. Hint never sourced or produced our product outside of the U.S., but we’ve certainly fielded many offers to do so. For us, sourcing all components here in the U.S. created a better environmental footprint. And while shaving costs might present a short-term benefit, shipping in bottles from overseas just didn’t seem right.

For any business these days, supply chain is key. If you can’t get the components that you need to produce your physical product, you are finished. While recent trade wars have caused many to move away from China for their sourcing needs, interruptions in overseas shipping and manufacturing (as well as increasing costs) have also solidified the importance of localization.

Today at Hint, we blow our bottles and caps right on the line and in manufacturing plants as close to our distribution points as possible. Saving on gas and trucking costs helps the bottom line. And sourcing all of our components here in the U.S. during the past 18 months gave us a production advantage at a time when other brands struggled with overseas supply chain disruptions.

It’s Time to Go Direct

I’m sure if Henry Ford were around today, he’d be delivering cars directly to people’s doors, much like startups Carvana and Vroom. Having a direct line to consumers has never been as critical. It should seem obvious that being solely reliant on retailers to deliver sales for your product poses a major risk. Being able to communicate directly to consumers that you are open for business and can deliver is not only smart but essential.

We were fortunate in that we started our own direct-to-consumer business in 2012, back when most of our competitors dismissed it as a distraction. But what we have seen throughout the growth of this channel is that the consumer who buys Hint from us on our site will also walk into a retailer and purchase it there too. The more options the consumer has to buy your product, the better. And multiple sales channels do reinforce each other.

Prognosticating is never foolproof. Consider the challenges you’ve had in your business and weigh what possible lessons can be learned. Think today about what you can do to better your business for the next challenge that awaits.

The future will reward you.